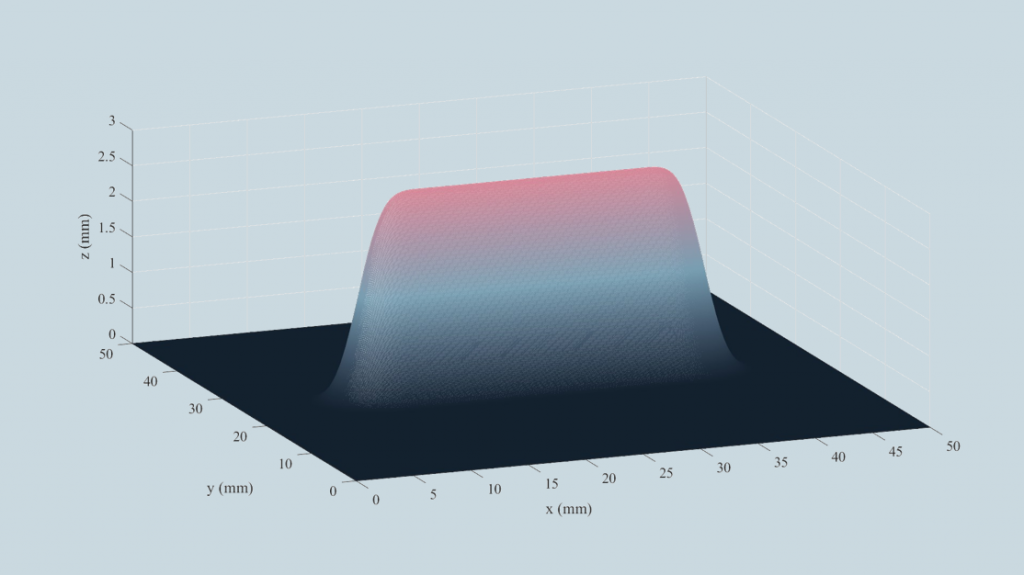

Shape control in solid state additive manufacturing

Among the many qualities of Cold Spray, its ability to create large and thick deposits with a wide range of materials and limited temperature effects has made it a highly promising technology for Additive Manufacturing. Accurately predicting the shape of the deposits and its correlation to working parameters is a key enabler for its future developments, as geometry control is currently one of its main hindrances. We are working by combining physics-based and machine learning approaches to develop comprehensive and computationally efficient shape prediction models for Cold Spray Additive Manufacturing, while concurrently optimizing the tool trajectory towards superior geometrical accuracy.

Recent publications

-

Outlook of Industry 4.0 Integrated Technologies in Thermal Spray Processes and ApplicationsNovember 10, 2025/0 Comments

Outlook of Industry 4.0 Integrated Technologies in Thermal Spray Processes and ApplicationsNovember 10, 2025/0 Comments -

-

-

Deposit shape control for local repair and welding by cold sprayJanuary 19, 2024/

Deposit shape control for local repair and welding by cold sprayJanuary 19, 2024/