Archès Lab's Specific Equipment

We are users of the high pressure Cold Spray system (Impact Innovations 6/11) equipped with ABB IRB4600 Robot installed at the DynAM Lab and have access to the numerous shared facilities of the Mechanical Engineering Department at Politecnico di Milano.

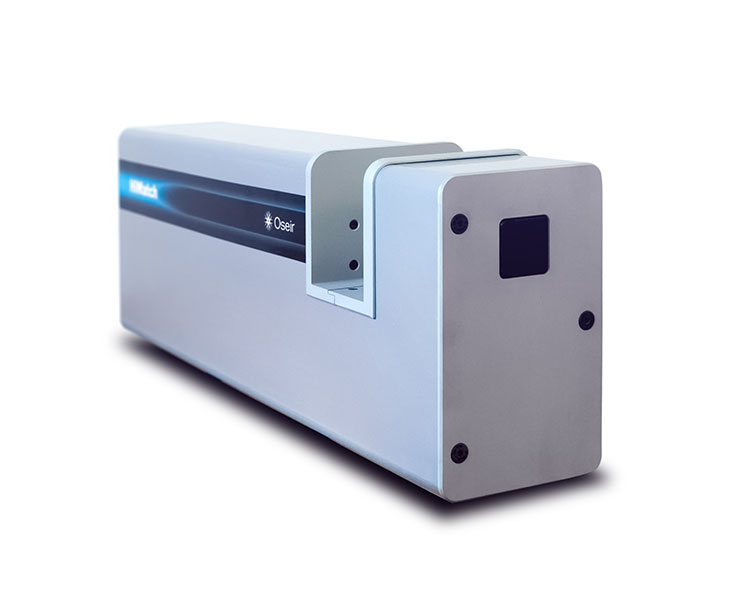

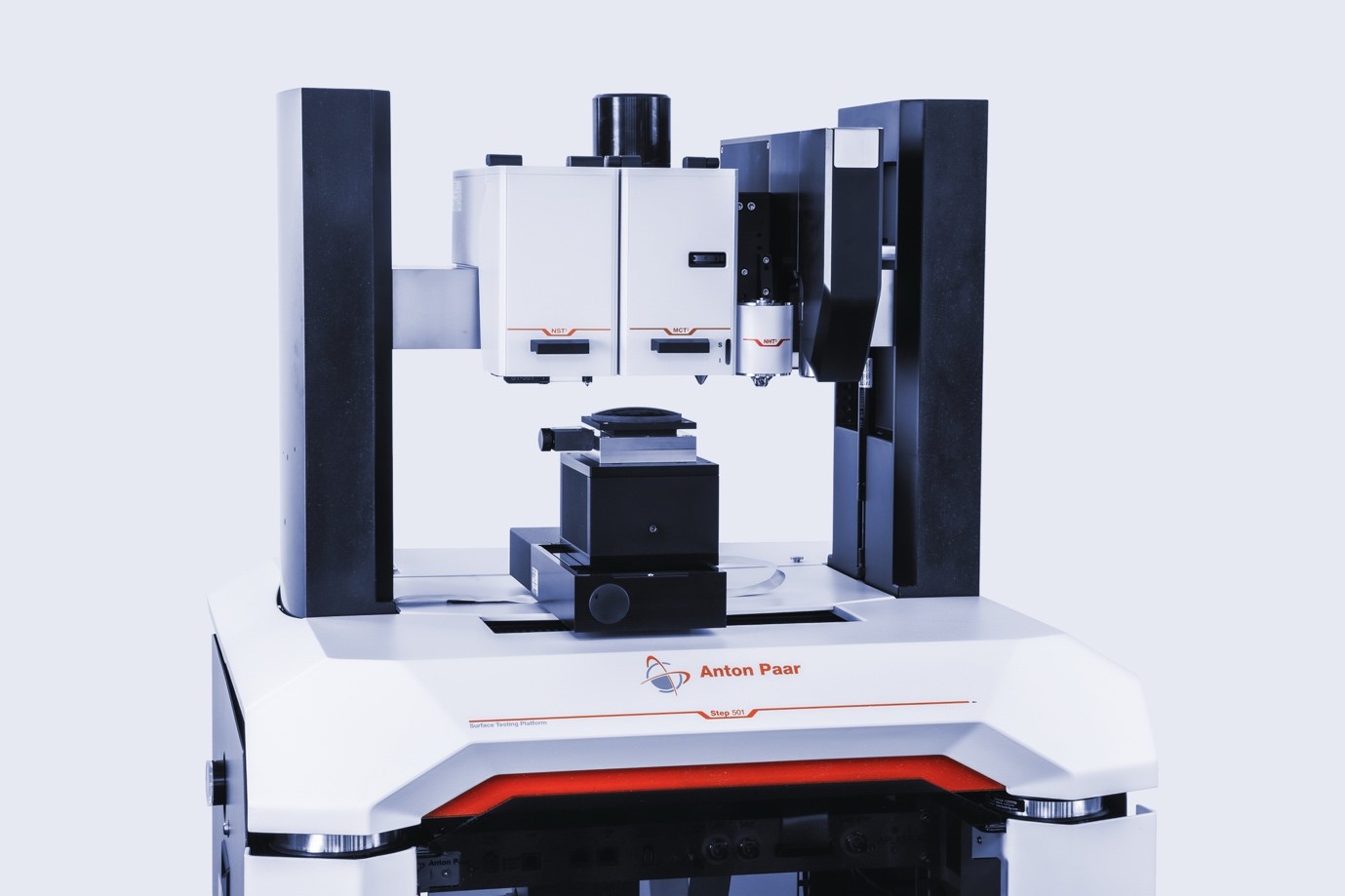

Some of Archès Lab's specific equipment are: