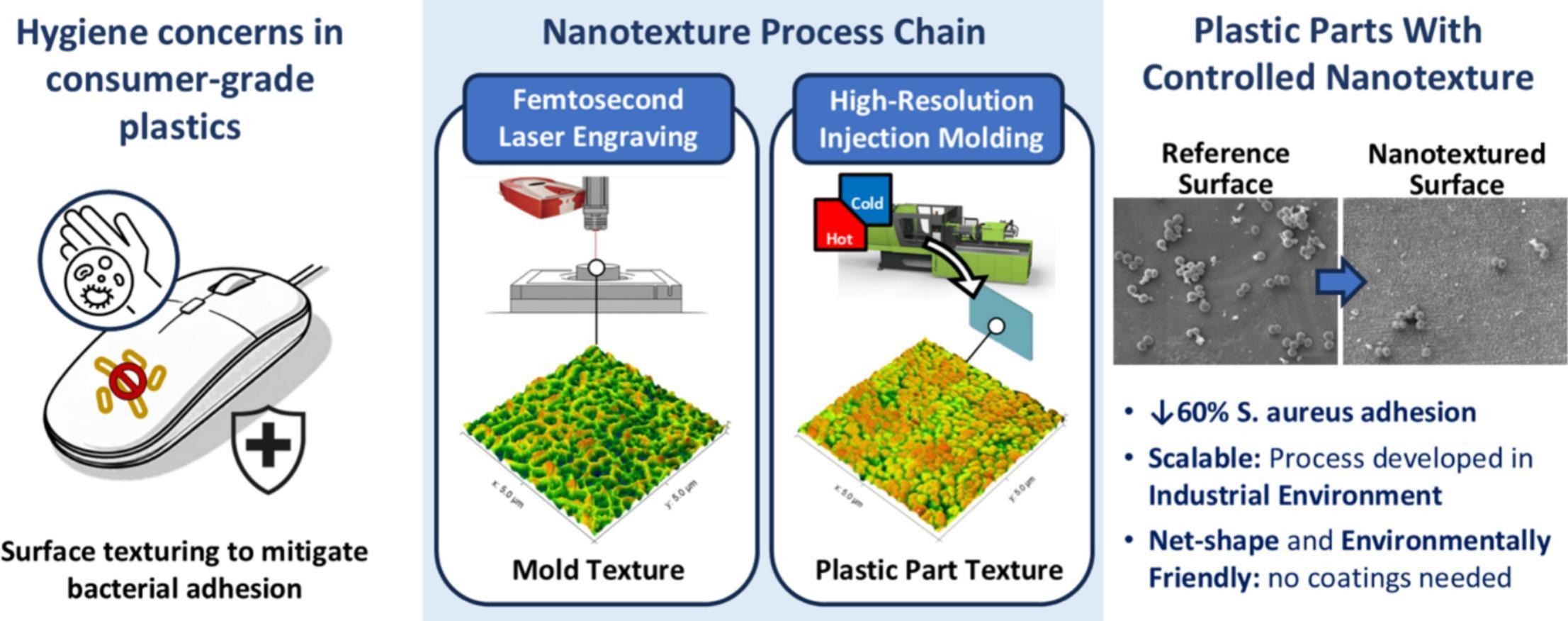

We are happy to share our latest publication, titled “A process chain leveraging femtosecond laser induced nanotextures towards mitigating Staphylococcus aureus adhesion on plastic surfaces”. In response to escalating hygiene concerns, we propose a novel strategy to reduce bacterial adhesion on consumer-grade plastic surfaces (e.g. consumer electronics). Herein, we develop, for the first time in an industrial […]

News

This past Tuesday, November 11th, Prof. Sara Bagherifard took part in the “ERC Funding Opportunities” event organized at Politecnico di Milano. The meeting, featuring George Symeonidis from the ERC Executive Agency, provided insights into upcoming ERC Starting and Consolidator Grant calls. Prof. Bagherifard shared her experience as an ERC grantee, offering valuable advice to researchers […]

We are excited to share our latest publication: “Outlook of Industry 4.0 Integrated Technologies in Thermal Spray Processes and Applications”. The purpose of this study is to provide a comprehensive review on the technologies of Industry 4.0 already integrated with thermal spray processes to uplift their applications through advanced digitization and automation, leading to enhanced […]

Our team participated in the 15th International Conference on Shot Peening, which took place at Purdue University in West Lafayette, Indiana, USA, between September 22-25, 2025. Prof. Mario Guagliano gave the plenary lecture of the conference on the topic “From Shot Peening of Historical Pompeii Walls to the Redesign of Roman War Machines: A Reverse […]

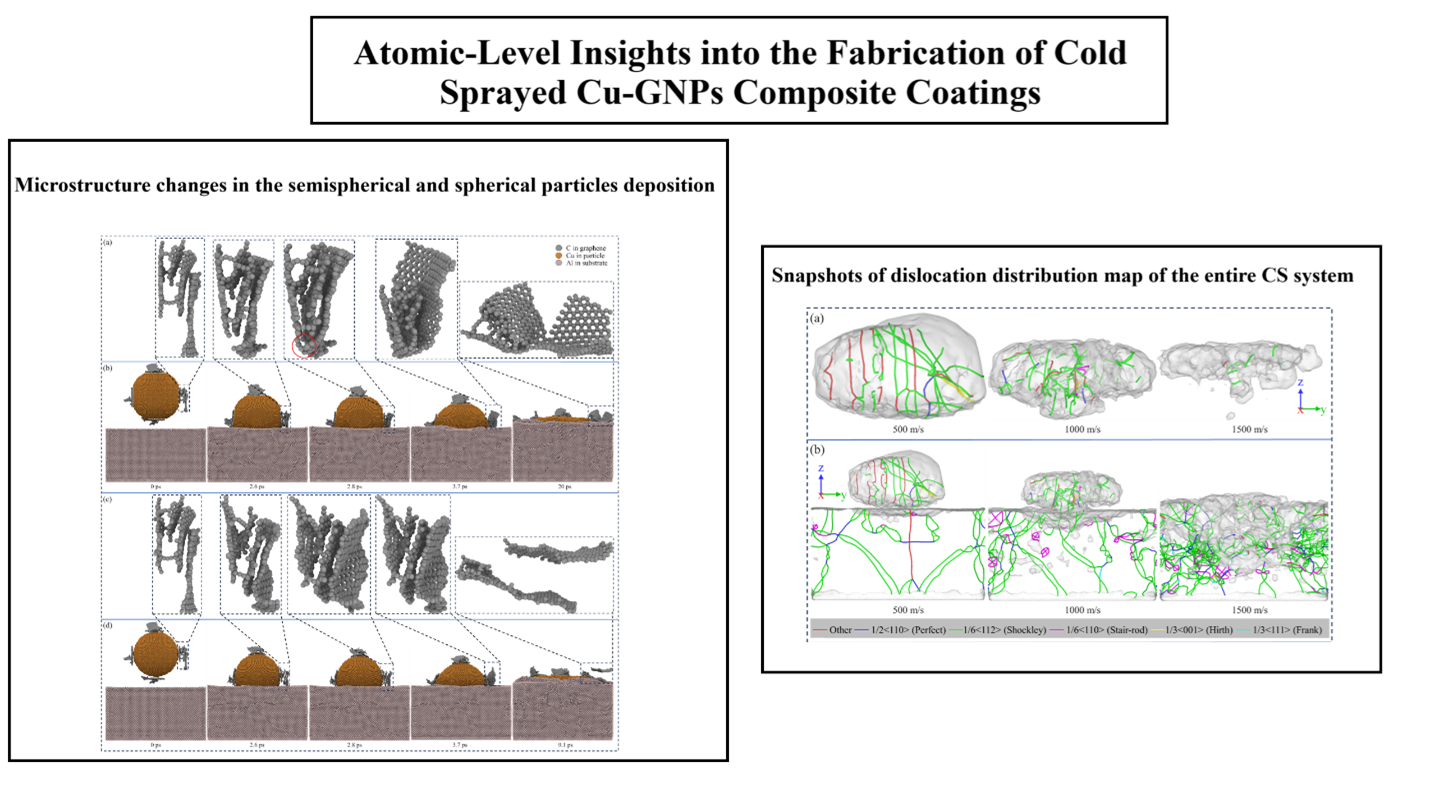

We are happy to share the most recent publication from Archès Lab in Atomistic understanding of physic behind the Cold Spray of Graphene-Cu nanocomposite powders: “Atomic-level insights into cold spray deposition of Cu-GNPs composite coatings” Molecular dynamics simulations revealed that cold spray deposition of Cu GNP composites on Al substrates is governed by dual bonding […]